What is Liquid Applied Waterproofing Membrane (LAM)?

Liquid Applied Waterproofing is a process of waterproofing application using special liquid. It’s used for roofs like flat roofs, pitched roofs, domed roofs and walls also.

Liquid applied Membrane involves Fully bonded monolithic coating application. This coating once cures forms a rubber like elastomeric waterproofed membrane.

LAM are flexible enough to take any shape they are laid to, also they have properties like strength, tear resistance, weathering resistance, UV stability & elasticity to bridge the cracks developed underneath the surface.

These kinds of membrane has excellent elasticity and they regain the original shape without any damage to the membrane when removed from tension.

LAM can be reinforced with secondary level materials like fibre glass or glass reinforced plastic to add more tensile strength to the membrane. Once these secondary materials are added the LAM losses the regain-ability.

LAM when applied, encapsulates the surface they are installed to and thereby preserves its underneath from weathering.

LAM are easy in application and are high performance waterproofing material along with economically viable waterproofing solutions for exposed and covered roofs.

Liquid applied Waterproofing membranes are mainly applied on above-ground envelopes. These are not advisable for the below-grade structures.

These systems are air cured quick drying, so any Waterproofing contractor in India would try to finish entire surface area in a single day or in a continuous shift to avoid formation of cold joints. However, in extreme giant area of waterproofing work, these cold joints are overlapped by few feet and rest in taken care as normal.

Read More: History of Liquid Waterproofing

What is Pre-Formed Waterproofing Membrane (PWM)?

Pre-Formed waterproofing is also called Sheet based waterproofing. In this type of waterproofing, a layer of watertight material is laid over surface and bonded to surface with varieties of options like Torch, Adhesive or Primer etc. PWM membrane composes of multiple thin layers of such waterproofed materials and bonded together to form pre-formed waterproofing membrane. Ideally, these membranes comes in thickness of 2mm to 4mm in a roll form and in verities of width ranging from 2′ (two feets) to 10′ (ten feets) depending on application purpose. They are overlapped to each other by minimum of 2″ (two inches) to 4″ (four inches) and are bonded with each other by help of hot polymer based adhesives.

Pre-formed membrane comes in different types:

- Bitumen based

- PVC based

- EPDM based

- Chemically Treated Fabric Based

The main caution zone of these membrane based waterproofing treatment is joint processing & bonding to the mother surface.

These systems are stiff, relatively less elastic than LAM, but they are highly durable due to their thickness.

These systems are usually proposed in below-grade waterproofing systems. Yet now-a-days they are also been applied to open to sky and covered roofs.

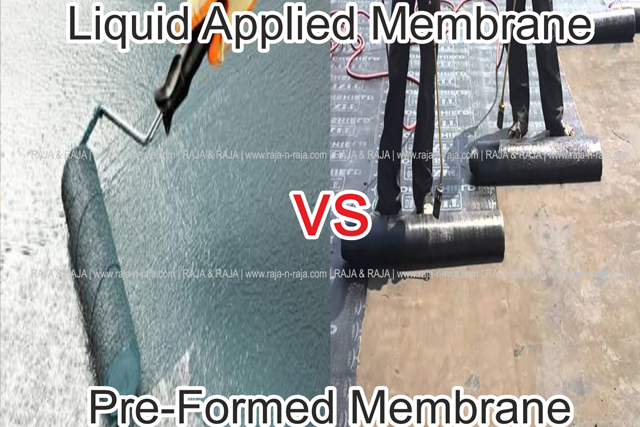

Liquid applied continuous membrane based waterproofing vs Pre-formed membrane based waterproofing

It is always an often question we get hit by many of our clients, who ask what better option between a Liquid is applied membrane & pre-formed membrane. Just thought to share a quick comparison chart between Liquid applied seamless membrane-based waterproofing using polyurethane, acrylic based vs pre-formed membrane-based waterproofing using EPDM, PVC, Bitumen membranes.

| Property | Liquid Applied Seamless Membrane | Pre-Formed Membrane |

|---|---|---|

| Ease of Application | Fairly Yes | May be |

| Workman skill | Skilled Labour Preferred; Semi-skilled Labour Must |

Skilled Labour Must |

| Application at Cornered Surface | Easy | Difficult |

| Thickness of System | Variable with application In Microns; at extreme in millimetres |

Non Varying Throughout & In millimetres by default |

| Fully Bonded System | Yes (Priming recommended in few cases) |

Not always; to be bonded with special adhesives & tapes A few comes with self-stick) |

| Number of Joints | No Joints (Monolithic System / Joint-less System) | Joints across the widths of membrane |

| Repair-ability | Easy & Quick | Difficult & Bit time consuming |

| Elasticity of System | Good | Poor |

| Weathering Resistance | Moderate | Higher due to its thickness |

| Ageing 0f System | Moderate | Relatively More Longer |

| Installation Period | Low | Relatively Higher |

| Recommended for | Above Grade Structure | Below Grade Structure |

| Overall Feasibility | Excellent | Average |

| Types / Categories | Bituminous, Polyurethane, Polyurea, Acrylic, Cementitious, Thermoplastic Etc. (Mostly all are cold applied, except a few) |

EPDM, PVC, Bituminous, Hybrid (Hot applied or cold applied) |

*Above shared details are as per waterproofing contracts experience & waterproofing products available within India and commonly used.

These details might alter as per country to country & cases to cases.

Hope the above brief helps you get the better idea in a schematic format and helps selecting better system as per your project / site requirements.