Silicone Membrane Roof Coatings – An emerging Roof waterproofing technology in India

It is a well-accepted fact that a building’s roof can be a major source of water leakage into the structure and its waterproofing needs considerable attention during the construction stage.

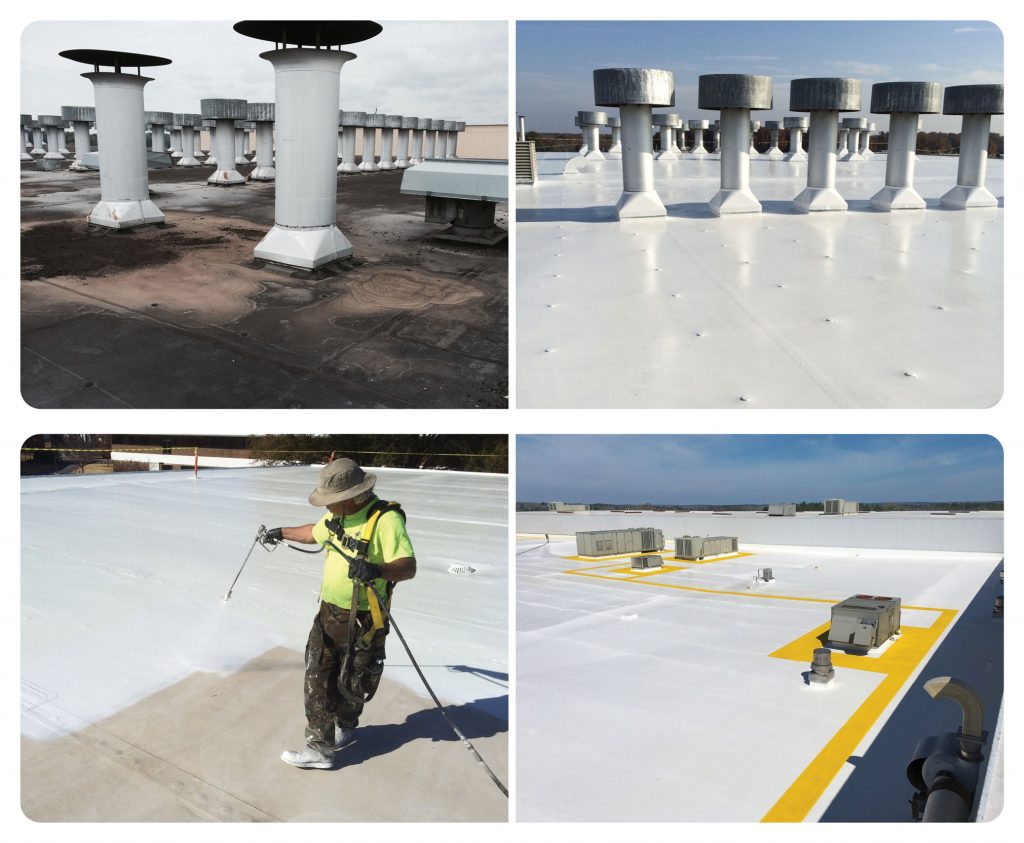

However, as building ages and the quality of construction deteriorates, external waterproofing treatments need to be undertaken. Several such treatments, with varying degrees of cost and technical complexity, are available in India. Amongst these, liquid-applied membranes (LAM) are finding increased acceptance on account of their simplicity and performance.

In this product category, the waterproofing treatment comprises of a liquid that is applied on the surfaces, and cures/dries to form a seamless polymeric envelope on the entire applied surface structure.

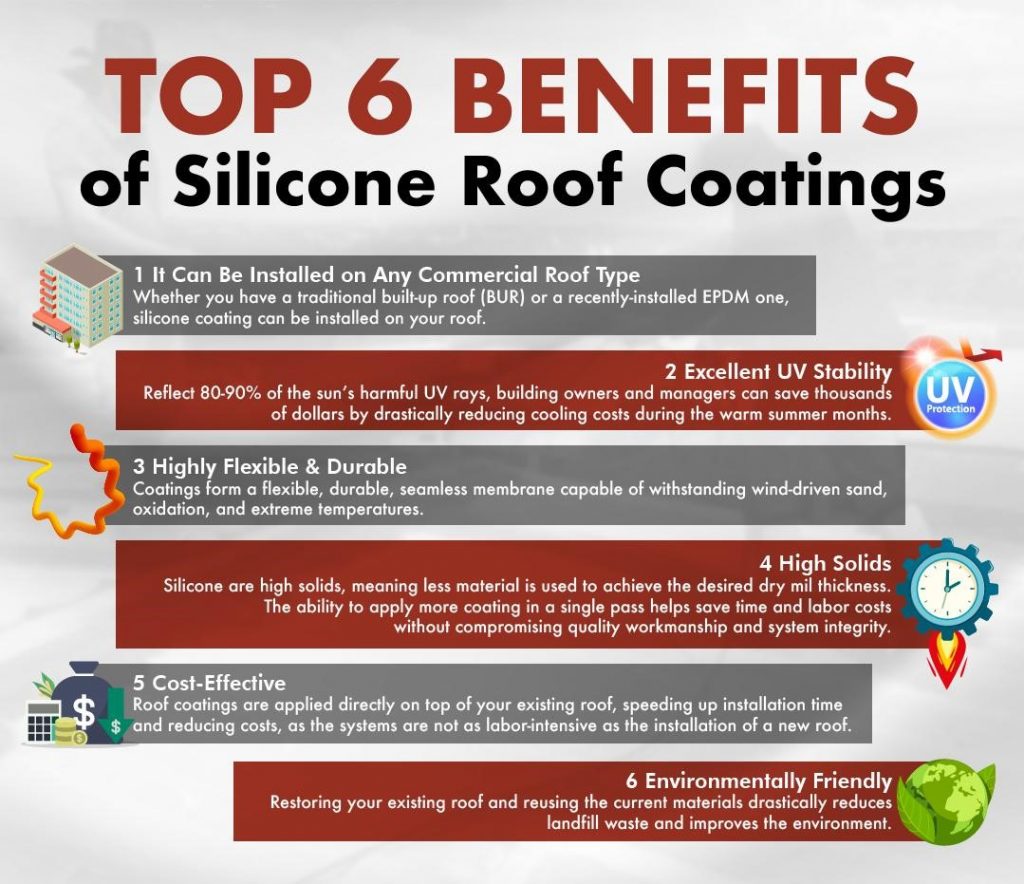

When selected properly and applied in compliance with guidelines of application, this method increases the life of the surface by several years (especially roofs), without the need to replace the entire roof structure. In addition, white-coloured membranes also offer a Cool roof effect due to reflection of solar radiation, which results in considerable savings in building cooling costs, especially during the harsh summer months.

In India, this is a well-established product category with several suppliers offering liquid applied membranes based on acrylic, polyurethane and polyurea technologies, with unique advantages and disadvantages of each chemistry.

Silicone-based Liquid Applied Membrane (S-LAM)

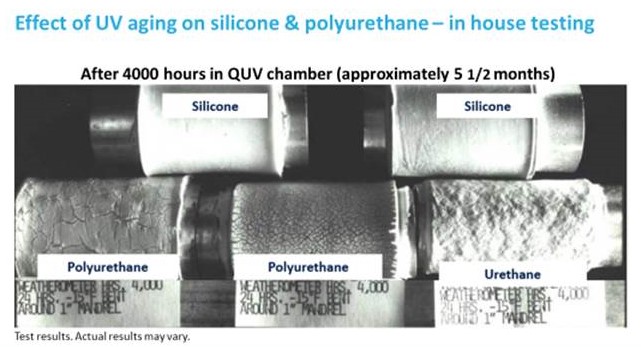

Made from elemental silicon, silicones are a special class of polymers that offer exceptional flexibility and have a superior ability to resist damage caused by exposure to the elements. Unlike acrylics or polyurethanes, the silicone backbone is inorganic, and therefore, does not degrade under UV radiation sources such as sunlight.

Silicone-based or silicone sealants are well-known in the façade industry and weatherproofing applications for just such benefits, and last for decades. The below picture shows how a typical silicone coating retained its flexibility vs three market-leading polyurethane coatings when wrapped around a mandrel after exposure to UV light for almost 6 months:

A roof-coating made from silicone polymers translates these advantages for a waterproofing application. Silicone-based liquid membranes are highly flexible to accommodate roof movement due to temperature variations, wind uplift, and resist crack formation.

Additionally, silicone membranes are breathable. They keep out liquid water, but allow transport of water vapour across porous substrate such as concrete and spray PU foam, which reduces the risk of blister formation. Well-known and standardized as a roof-coating in and around the western globe, silicone membranes (SLAM) are emerging in the Indian waterproofing market.

Lastly, silicone products generally are set within two days of application – an important consideration for contractors dealing with labour shortages and strong demand for their services.

The table below summarizes the superior benefits of silicone-based liquid applied coatings in comparison to other polymer-based roof-coatings, one of the best roofing products in India with harsh summer conditions, and a short yet concentrated rainy season.:

| Acrylics | Urethane / PolyUrethane | PolyUrea | Silicone | |

| Curing Process | Evaporation | Chemical Reaction | Chemical Reaction | Chemical Reaction |

| Application Process | Brush, Roll or Spray | Roll or Spray | Spray Only | Brush, Roll or Spray |

| Number of Coats to be applied | 2 to 3 | 2 to 3 | 1 to 2 | 1 to 2 |

| Vapour Permeable | Yes | No | No | Yes |

| Water Resistance | Good | Better | Better | Better |

| UV Resistance | Better | Good | Poor | Better |

| Weather Resistance | Better | Better | Better | Better |

| Elongation | Good | Good | Good | Good |

| Surface Hardness Range (Shore Hardness – A) | 50-95 | 75-85 | 80-90 | 35-80 |

However, not all silicone roof coatings are the same. Silicone coatings that have high solid content (fewer application passes), are VOC-compliant (no harmful solvents) and offer primerless adhesion to most substrates (fewer number of coatings) are the most attractive. Furthermore, silicone coatings based on alkoxy curing technology have no offensive odour and are, therefore, highly preferred, as per table below.

| Acetoxy | Methoxy | Oxime | Alkoxy | |

| Odour | Vinegar | Ammonia | Solvent | Neutral |

| Off Gas | Acetic Acid | Methanol + Ammonia | Methyl Ethyl Ketoxime | Methanol |

| Feature Used as | Sealants (Caulks) | Sealants (Caulks) | Sealants (Caulks) & Coatings | Sealants (Caulks) & Coatings |

| Primer Less Adhesion | No | No | Might be | Yes |

| Mixing Required before application | Not Applicable | Not Applicable | Yes | No |

This feature also becomes important when your water-proofing job is on a hospital or school roof, where the resulting odor from a job will not be acceptable for occupant safety.

When silicones should not be used

Despite ease of application, silicone liquid applied membranes (SLAM) are specialty roof coatings and need expertise in roof pre-treatment and application. Secondly, every leaking roof is unique and there is no ‘silver bullet’ solution that works in all scenarios. This is true for silicones as well, and the use of most silicone roof coatings is discouraged in the following scenarios:

- Ballast Membranes

- Aluminized coatings

- Tar Pitch Surface

- Gravel Surface

- Wet Surfaces

- Heavy Traffic Areas (Roof top deck)

- Steep Roofs

- Concrete (over pH 10)

In summary, Silicone technology offers unique advantages over other liquid-applied roof coatings and is a valuable addition in an applicator’s toolbox of waterproofing technologies. Please reach out to us to learn more and determine the suitability of a silicone-based roof coating product for your unique waterproofing situation.